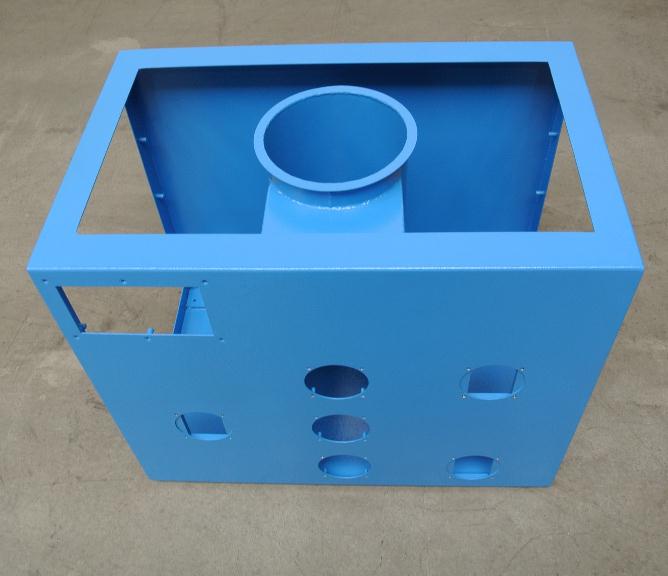

laser-cut & press-brake components

We manufacture complete machines out of laser-cut or press-brake manufactured parts:

- typical wall thickness of 1 - 5 mm, in comparison with classic welded parts with 5 - 100 mm thickness

- by reducing wall thickness we create lighter and less dear parts

- sheet metal can be laser-ed or cut classically

- when the parts are laser-cut, many further windows and cutouts can be realised without increasing cost

- laser-cut parts can then be bent or stamped on a press-brake, up to 6m length

- even larger parts have to be welded carefully, so that the work is invisible after painting

- our suppliers are equipped with modern Trumpf machines, so that the laser work and the bending can be made on the same machine

- large formats and strong thicknesses are manufactured on separate press-brakes

- when parts have only simple functions as a cover or a bracket, manufacturing is ending at this stage

- however, if strong and stiff parts are needed for machines, the parts usually have to be welded to form complete round or cubical structures

- of course different materials like steel and aluminium can also be joined, provided that welding is possible

Further manufacturing steps can be:

- riveting or stamping of threaded rivets

- spot-welding of threaded bolts

- classical machining of course, but for direct cutting of threads the wall thickness usually is not strong enough

- painting the parts with wet paint or powder coating

- sealing the edges against water or air, before or after painting

- and of course assembly with further components, seals, etc.

In comparison with classical welded components out of flame-cuts:

- due to the lower wall thickness the laser-cut parts are lighter, but of course not as stiff towards bending and shearing

- the expense for programming the laser and the press-brake is worthwhile for series parts, but not for individual components

- even though laser-cut parts are bent on the same machine automatically, there still remains a lot of manual work, especially if the sides have to be finally joined by welding

- welding seams often are potentially visible for the final customer and have to be carefully welded and polished

- theoretically laser-cut and bent parts form a parallel joint line, that has only to be welded

- however, practice shows that these parts first have to be straightened and clamped before welding, so that a high level of workmanship is necessary

- in order to produce beautiful welds on these parts, sometimes even longer than 6m, not many experts are available; standard craftsmen are not all alike

- it is financially not interesting to replace standard stock profiles by laser-cut parts

- however, when the laser-cut parts are well designed and manufactured, they achieve a certain "lightness", that adds to the good design of the total machine and that is also honoured by the final customer

We can manufacture parts and components for machinery by 3 different technologies:

- as castings

- as welded parts out of flame-cuts, typically 5 - 100 mm thick

- as laser-cut or press-brake parts, typically 1 - 5 mm thick